PREMIER LASER CUTTING & METAL FABRICATION COMPANY

With precision fiber laser cutting, press brake bending, PEM insertion, and part fabrication services.

State-of-the-Art Services

With precision fiber laser cutting, press brake bending, PEM insertions, and part fabrication services, we’re well equipped to complete any job accurately and precisely.

The R.I.C. MetalWerx Advantage

When we say quality, we mean a commitment to making products that you will be happy with every single order. R.I.C. MetalWerx produces high quality metal products in our conveniently located facility, specializing in highly-accurate laser cutting, bending and assembly, and we are experts in working with mild steel, stainless steel, aluminum, copper and brass. All metals we work with can be cut up to 1” thick!

We strive to exceed our customer’s expectations and promote change through our continuous improvement efforts, while providing a safe and teamwork-based work environment. Our team embodies an entrepreneurial spirit, and because of this, we can run our business in a way that is efficient and innovative.

OUR MISSION

Service We Provide

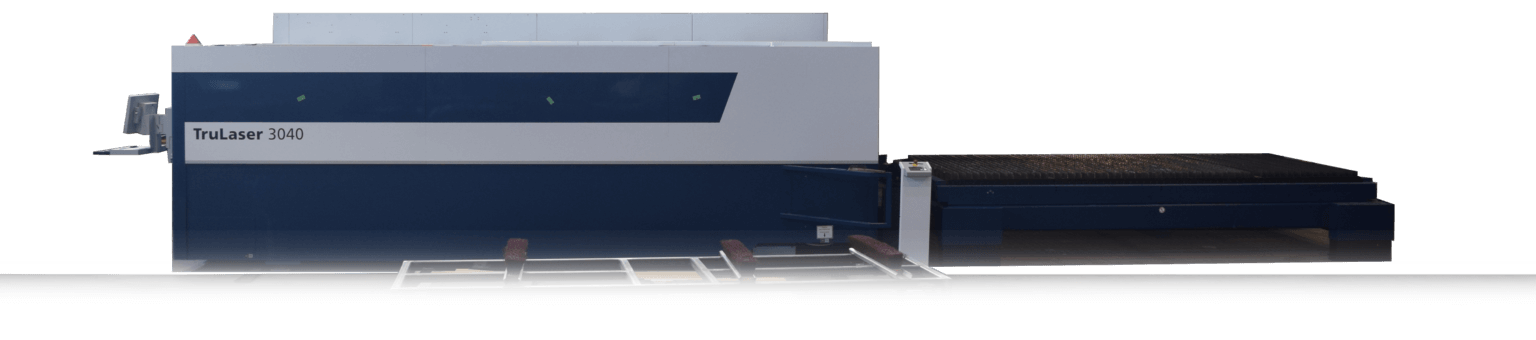

Fiber Laser Cutting

Press Brake Bending

PEM Fastening

We Specialize in:

- Complimentary consultative design process review

- Analyzing procurement and processes to find the best fit

- Lead time reduction strategies

- Cost reduction through training, technology and process improvements

- Employing industry best practices to ensure on-time, defect free products

Our facility is equipped with the latest CNC equipment to facilitate high volume production-run manufacturing. Manufacturing processes include Trumpf Laser cutting, Press Brake forming, Pemming and CWB certified welding. Our engineering department is equipped with dxf and SolidWorks software, and custom design services are available. We are able to download and accept many file types, such as DXF and STP. R.I.C. MetalWerx is ISO 9001:2015 certified to ensure consistent high quality for all parts and components. We are also certified under CWB – The Canadian Welding Bureau.

The R.I.C. MetalWerx Advantage

When we say quality, we mean a commitment to making products that you will be happy with every single order.

Quality Management

Modern Equipment

Request a Quote

Frequently Asked Questions

If the order is laser-cut only, DXF drawings are ok. If there is any sort of forming in the order, drawings have to be STEP or SolidWorks files, or else we need the extra time and cost for programming.

Attach them to the contact form or include them as an attachment in your email.

Yes, dimensions measured to the 1/16th and tolerance requirements are preferred so that we can make the most accurate products for your projects.

Absolutely they are, just let us know ahead of time!

We accept credit cards, EFT, cheques, cash, and wire transfers, though we cannot accept e-transfers.

Yes it can, if that makes the process more convenient for you!

We can ship anywhere in British Columbia, Alberta, Saskatchewan, Washington State and Northern Oregon, and if you let us know early, we can even include the cost of shipping in the quote.

Yes they can, and we can even include them in the quote when you place an order.