Press Brake Bending

Also known as a brake press, brake, or simply a bender, this is one of our most important pieces of equipment.

It allows us to give metal parts the most precise bends possible with a quick turnaround time.

Brochure

Download our document to see specific data of our services and how we work.

Let’s Start Work

Together

Please feel free to contact us. Quotes requested before noon will be replied to same day.

Press Brake Bender Specifications

Our press brake bender is a Trumpf TruBend 5170.

It operates with 180 tons (1765 kN) of press-force.

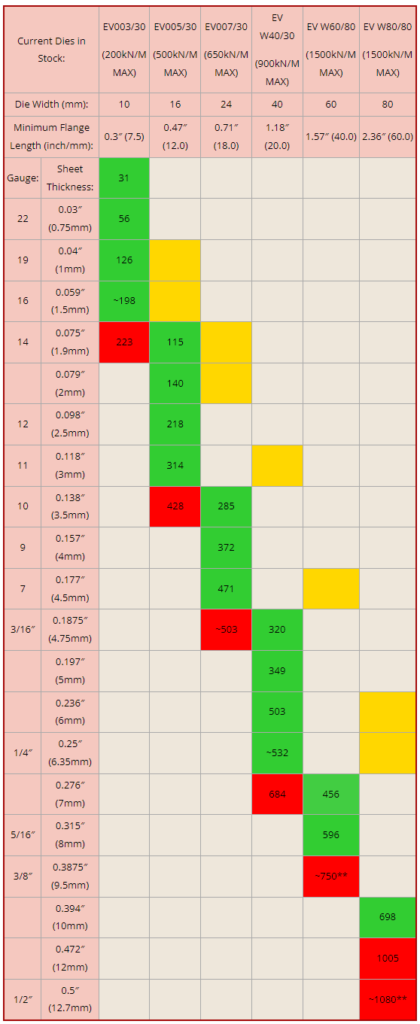

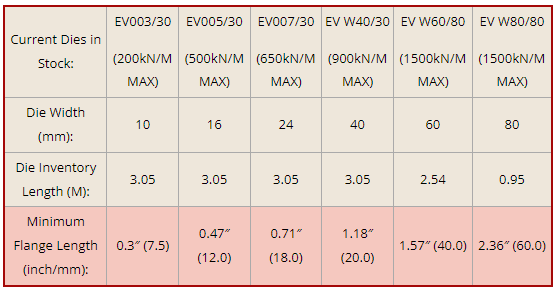

It presses metal into die with widths of 10, 16, 24, 40, 60, and 80 millimetres to create the tidy and precise bends you see on finished products. You can read about the applications of each width of die in the charts below.

It can bend any of the metals we work with – mild or stainless steel, aluminum, copper, or brass.

It can bend parts up to 106 inches long with a flange longer than 16 3/4 inches, and parts up to 127 inches long for any flange shorter than that.

It can also bump metal into shapes such as cones with large radii.

It’s capable of complex, high-accuracy bending jobs to ensure that you get parts that are as precise as possible.

The thickness of metal that we can bend with our press brake depends on the width of the die that we’re pressing it into. Here are the thicknesses possible with the die we currently have:

Note: red = minimum die width, green = best choice die width, yellow = maximum die width, ~ = approximate value, ** = values to be confirmed possible in TruTops

The flange size also depends on which die is used, and how tightly that die can bend the metal part. Here are the minimum flange lengths we can bend with our current die:

The maximum flange size also depends on the material length. Because of the shape of the press brake bender, if the material is shorter than 106 inches, the flange can be very long (greater than 48 inches) as there is room for it in the back of the machine. If it is 106 inches or longer, the flange can only be 16 3/4 inches, because there isn’t room for more material behind the die to the side.